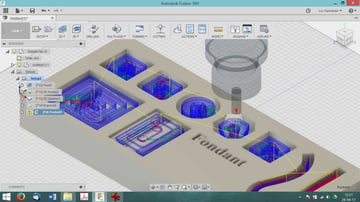

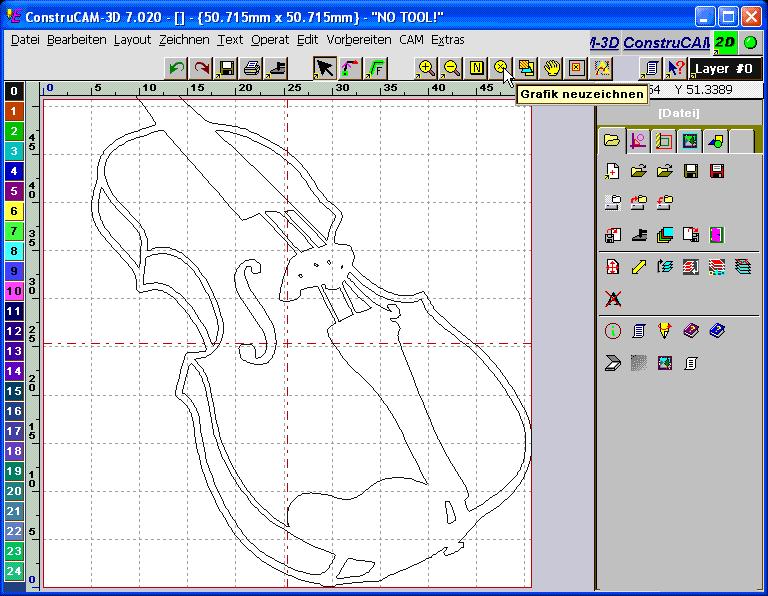

enabling programs to be modified for use on other jobs with similar specifications.automatically translating the designs into instructions for the computer controller on the machine tool, and.The operator is then able to specify the machining operations required and the CAM system will integrate these into a CNC program.Īlso, the link between CAD/CAM software and CNC machines increases productivity by: download the proven program to the CNC machine.run a simulation on the screen to prove that the program works, and.With its single, shop-friendly interface that is customizable and easy to navigate, you’ll maximize productivity. do all the programming on the computer, GibbsCAM ® is cutting-edge CAM software for programming CNC machine tools with the power and flexibility to make parts the way you want.When using a CAD/CAM system the programmer is able to: Now, once the machining operations to be performed are specified by the operator, CAM will automatically create the CNC program. Before the integration of a CAD/CAM system, CAM had to re-create the model produced by the CAD system before it could create a program. This means that a drawing done in CAD will automatically be configured in CAM.

CAD is a software package that assists the programmer to draw and design the product while CAM is a software package that assists the operator to run the CNC machine. CAD (Computer Aided Design) and CAM (Computer Aided Manufacturing) software is used extensively throughout the furniture making industry.

0 kommentar(er)

0 kommentar(er)